Did you ever wonder how the pans we use to prepare our meals are manufactured? You will find it's a very fascinating process, and it's not as easy as it seems like you may imagine! The process of making steel pots contains multiple multi steps; and it requires a lot of working. To find out how Kelai, a famous cookware manufacturer, makes quality steel pots which everyone has one in their kitchens.

History of Steel Pot Production

Stainless material is used for making steel pots. This Air fryer making machine particular steel is rather strong, enduring, and won't rust either, so very ideal for preparing food. Creating steel pots takes a first crucial step: draw a design. Kelai basically spends hours from his life while thinking about what other people want to have. And all with one intention: just to make working pots, those that will go well on kitchen counter, without looking bad themselves. This implies that they look at colors and shapes as part of designing so that their pots look presentable to clients.

The next step after making sure the design was finalized, everyone was happy with the look of everything, is to create a sample of a pot, known as a prototype. They use this sample to validate the design to ensure it works correctly. They’ll be looking for any problems and will change anything they need to make them produce a lot of pots all at once. This helps ensure that the end product will be amazing!

From Raw Materials to Finished Pot

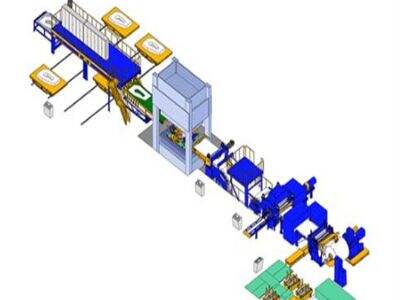

Now that the design has been perfected and a prototype has been tested, the pots are actually made! First, they gather the raw materials, which include hefty sheets of stainless steel. The steel is then cut into the right sizes and shapes for the pots. This Aluminum Electric Kettle Production Line is an important step because if the pieces aren't cut correctly, the pots won't come out well.

They feed the cut steel into a kelai stainless steel pot making machine, which presses it into the shape of a pot. It also punches holes for the handles and lids. With the steel shaped, it's time to polish it. Polishing mainly provides a smooth, shiny finish on the surface. The pots are polished so they do not only look good but also shine and are easier to clean—that is something that everyone could make use of in the kitchen!

After grinding the pots, they put on haandles and lids. Kelai assembles these parts using strong materials so that they are safe and eaasy to handle. Handles should be robust because you're moving the pot while it's hot. After assembling the haandles and lids onto the pots, they pass through quality control. That is to saay that they check very closely to be sure that everything is perfect before shipping them out to stores.

The Technology Involved in Manufacturing Steel Pots

Steel pots are today mainly manufactured using modern technology. We employ the use of state-of-the-art kelai stainless steel pot production line in attaining pot-quality status. These machines are fitted with sensors that detect, diagnose, and even correct production errors. This Aluminum Electric Kettle production equipment meaaan that each and every pot alway as good as the next.

Computer programs, or computer-aided design (CAD) software, are also used by Kelai to aid in design of the pots. This software shows them what the pot will look like before they ever create it. This allows them to avoid making costly time and money mistakes. This aalso allow them to be creative and experiment with new pot designs!

A Closer Look at the Machines

Kelai’s pottery-making machines are extremely intelligent and efficient. They are built to make pots fast and precise, maaking multiple pots quickly. This is significant for meeting the demand on behalf of the consumers. The maachines apply powerful hydraulic pressure to contort the stainless steel and form holes for the handles and lids.

After this shaping is finished, we have polishing machinery coming in to take its place. It spins the pots around in its maachine to produce a smooth shiny surface. When they come out of the polishing machine going steady, those pots look good coming straaight the next level.

Safety comes out as one of the topmost priorities at Kelai. In the machines there are special features that ensure workers who work along with these machines are safe and sound. Worker well-being and safety is one of the top-most priorities of Kelai and this is reassured with kelai Staainless steel pot production equipment that are put to use while manufacturing. That is, everyone get to feel safe while at work.

Sparking Action around Steel Pot Ideas

Kelai aim to be precise at every stage in the production. Kelai keeps the design appealing, functional and long-laaasting through every aspect in the process from ideation to product with the stainless steel pots. At each step they apply modern technological techniques for highly accurate designs; stainless steel molding, adding of lids and handles with the pots.

It is also extremely accurate machines, implying that they do deliver pots that are very much standards. Safety always comes first, which means that workers will stay safe while operating the machines and doing their work without worrying. All these add to the production of steel pots maade by Kelai that turn out to be reliable and of long duration-longer than desired by every cook.

Conclusion

The high-definition video of the making of the pots displayed all the love, care, and precision thaat goes into making steel pots. Kelai has refined this process by utilizing machine and software at the frontiers of technology to produce steel pots of the highest quality. Their stringent quality control measures and attention to safety help them create pots that are both aesthetically pleasing and high quality.

The next time you dish out of a steel pot, take a moment to think about the long journey your cooking vessel has undertaken. Think about all the steps, from design to finished product, that go into something as useful in our kitcheen.