Steel pots have really been important players in our kitchens for a long time. In this kitchen, we cook all kinds of food: rice, pasta, vegetables, and many more. Ever wonder how those pots were made? Steel pots are a little tricky to manufacture. New machines make much more easily and more quickly now than when I started.

How Steel Pots Are Made

There was a time when preparing steel pots was labour and time taking. A worker had to bend and shape the steel to form pots manually. He did all that using hammers and anvils. This took time, and sometimes he would make mistakes. That work required much labour if many pots were to be produced. That is where the new machines enter to make the work easier and speed up the process.

Machine Tools Changing the Way We Produce Steel Pots

Now, with new machines, making steel pots is faster and easier than it ever was before. These new machines could take flat pieces of steel and stamp those into the desired shape of the pot in almost no time, operating at speed and having pinpoint accuracy for a very reduced chance of forming defects compared with human laborers. These fascinating machines have totally changed the way steel pots are made thereby making the product much easier for companies to produce.

More powerful machines for bigger pots

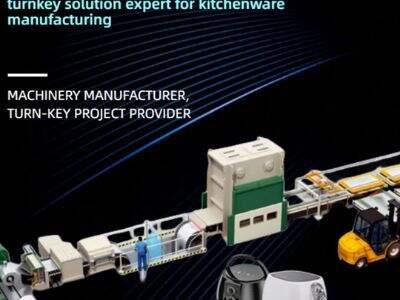

As people look forward to buying steel pots, manufacturers realize that they need better machines for them to respond to an increase in demand. Using large-scale automatic steel pot making machine, among many other machines at one time, can make this process very precise. This makes producers sell more of the pots as well as helping customers get all the pots that they need as long as one goes to shops.

How Technology Does Assist Speed Up Pots

Technology also has a part in helping to make the steel pots fast and quick. Computer programs now can create special molds that give the steel its shape — pots. Factories produce these molds, through which the machines fill pots in high speed. Many machines are also fitted with sensors that can tell when something is not operating properly. In case a fault is established, the sensors are activated, the employees will rectify it on spot. These are new technologies; they literally oversee the production of Steel Pots much more directly, with minimal fault, and such is what corporations demand.

Production of Steel Pots Change

Over the past years, there has been evolution in the fabrication of steel pots that is not by any means void of change- new machines alone. Not to mention, it is quicker to produce, easier to craft, and less labor-intensive to make pots. And the machines we are using today are far way off from those old hammers and anvils. Even the likes of Kelai are now operating some of the best machines in the industry to make sure they are producing high-grade steel pots people love.

For instance, the machine has no disadvantages but advantages; It can prevent people from polluting the whole surrounding environment through the old method of processing steel pots. Today, production is not only faster but also more efficient and precise. For companies like Kelai, this means access to new markets and the ability to meet the increasing demand for steel pots. With technology evolving the way it is, all this innovation within steel pots and cooking will soon be made available to every single inhabitant of this planet.