Steel pots are very important tools that people globally use in kitchens. The have helped us prepare a range of different food and they have been used for many years. But did you also know that new technology is revolutionizing the way these pots are made? Kelai is a popular category that produces kitchen items, employing machines and other advanced devices to bring forth improvements in the production of steel pot. In this article, we show you how technology is transforming the way we create steel pots and what this means for all of us.

Why Change is Needed

As global population rises it creates an ever-increasing demand for steel pots. With more human beings on Earth, there is a greater need for pots, and therefore companies have to produce more pots. Old fashions of making pots require many workers and time ante that can be expensive. It needed to change, Kelai saw, in order to stay on top of what people wanted and be successful. Through technology, the company can save time and money while simultaneously producing more pots. This allows them to deliver pots to customers when they need them, without lead time.

How Steel Pots are Made Now

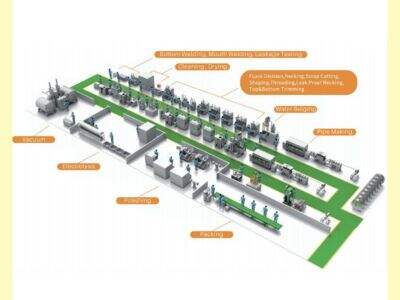

It is now based very much on the use of special machines that are made for making steel pots. Kelai has purchased a number of new machines capable of producing steel pots very well and very quickly. Potters remain busy on these machines all day and night producing a large number of pots faster than the traditional methods. With this, Kelai able to adapt with the market that can not escape from high demand for steel pots. Moreover, being reliant on machines makes it possible to ensure that each pot is of the same quality, something that is very important for customers who want to have faith in the brand they are purchasing from. Thereby, when customers are certain about the pot quality, they tend to come back to the brand.

Robots and intelligent technology

Kelai does not only limit herself to regular machines. Most everyone agrees that robots and smart technology referred to as artificial intelligence (AI) are the future of manufacturing, according to the company. In other words they are not simply content with how well the foil container making machine production process is going. For example, Kelai is already employing robotic arms that can safely and speedily move pots from one location to another within the factory. These robots allow them to make pots more efficiently, as well as keep the workers safe from performing dangerous actions.

AI can also be crucial for optimizing the manufacturing process. It analyzes data from sensors embedded all over the factory to identify problems and propose remedies. E.g AI is able to adjust the temperature in the furnace, this allows making sure that steel is getting better and the product itself with a higher quality. AI’s suggestions may include differences that the average non-expert producer wouldn't think would be noticeable, but on a larger scale can improve production and the quality of pot.

Steel Pot Production: Where We Go From Here

Kelai sees many golden opportunities to continue applying technology to steel pot manufacturing in the future. One area where less should make up more, so to speak, is the development of machines that can do more jobs themselves. This will ensure the production process is even faster, cheaper and better with more automation of processes moving forward. It also frees up workers to concentrate on other tasks within the factory that demand human skill.

Also, the use of 3D printing aluminium container machine technology would allow for a groundbreaking way of pot manufacturing. With 3D printers, we can make a model of the pot before we make it, rather than creating molds for each design. This will prevent errors, and ensure that the pots are created correctly. And with new designs emerging each year, 3D printing can help cut the time it takes to get new products in stores—without sacrificing quality. What this means is that customers will receive new and innovative products faster than ever before.

Keeping up with the Technology

While there are numerous incentives to change a steel pot manufacturing process, there remain hurdles that must be overcome. A major hurdle is constantly staying ahead of all the new tech released each year. The technology keeps changing and upgrading, Kelai needs to adapt to this evolution in order to compete in the market.

Rice: To stay ahead, Kelai spends a fortune on R&D to find the technologies that will help make Win a better manufacturator. The organization also collaborates with schools and practitioners to keep abreast of new theories and innovations. Partnering with the education institutions helps them learn the details of the latest advancements and incorporate it into the aluminum foil making machine production process.

Therefore, to summarise, Kelai more specializes in introducing advanced technology in steel pot production, which eventually makes pot better. So, they are looking ahead and will keep investing in ideas that can make the process more efficient since the end goal is to ensure steel pots the customers purchase on the market are higher in quality and come at a cheaper price. That means customers are assured of getting great pots that suit their needs needs while helping to power innovation in the kitchenware market. Kelai is regularly committed to improvement and is thus a brand you can trust for all cooking, thanks to this commitment.