Revolutionising Stainless Steel Pot Production in China

In both home and commercial kitchens, stainless steel pots are a staple tool. In china technology is being used to improve the process of making these pots. This article will go in-depth into the positive effects of these improvements on stainless steel pot production.

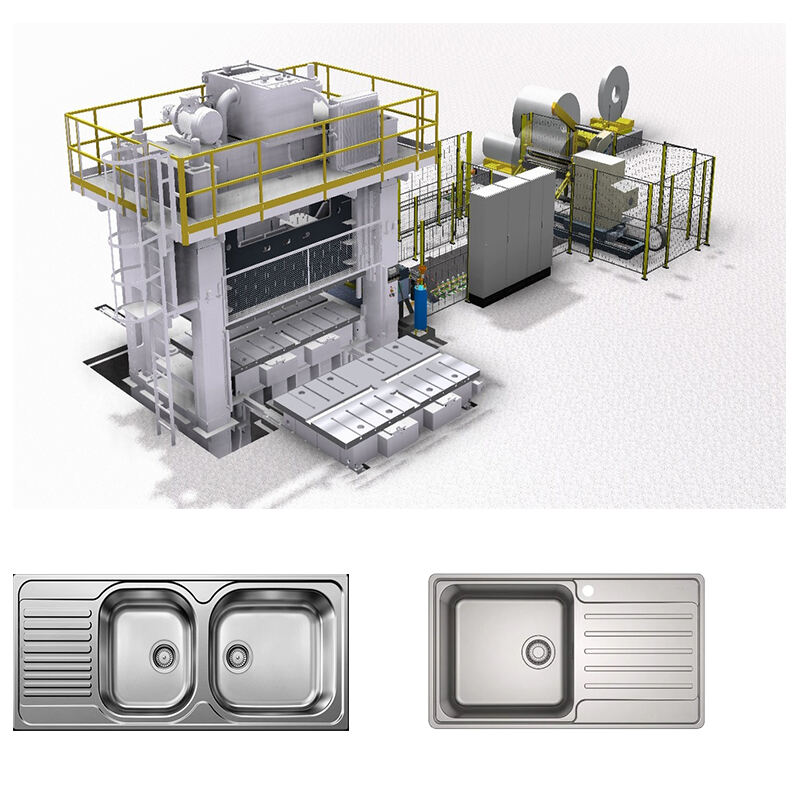

Benefits Of Employing Machines In Production

The biggest advantage to using machines in pot production is the tremendous gain there will be in speed and cost efficiency. This is useful in pot manufacture when machines ensure that the dimensions of a collection stay constant, so manufacturing errors do not lead to failures or recalls and extra time goes into production rather than replacement. And, the use of machines ensures a final product that conforms with market requirements - also in terms of price competitiveness.

New Developments in Automation Technology

One of the most significant advances in automated production is AI technology incorporation. AI can simulate human thought and processes to perceive problems of the issues quite faster. This does not only increase the safety of the production process, but it also increases its efficiency as a whole.

Security Protocols for Automated Production

The safest place in the fabrication of stainless steel pot is to pay more attention. Reduction of Human Interaction and Related Risk - Automated Production lines automated will reduce the dependence on humans thus ensuring workplace safety. Contributing to a Safer Production Environment by Minimizing Human Error & Fatigue

Characteristics That Are More User Friendly in an Automated System

Production lines are designed to be intuitive and can cover even by the not-technically-inclined. These systems are versatile and can carry out numerous types of manufacturing operations, so you may not require more unique equipment. Even a careful mixture of the ingredients and an efficient use of heat is guaranteed because the various input sensors assure precise measurements and temperatures - another sure way to improve consumer appeal.

Automated Systems Maintenance and Support

In order to maintain peak performance, automation production lines need regular maintenance. Good. maintenance is simple and can be performed by people at low levels of technical skill Moreover, the provider offers timely support from manufacturers for maintenance on different levels like training and availability of spare parts or upgrades to keep equipment well-functioning.

To date nothing can match the sheer versatility of automated production lines.

Given the high production demands in automotive and aerospace, for example, automated lines see use across a range of industries. In the stainless steel pot production industry, these machines play a key role in automation as they help standardize product quality and maintain uniformity of output while maximizing efficiency and safety.

In Conclusion

Machine use for stainless steel pot manufacturing can give the producers many advantages, such as reduced costs, better quality control and increased productivity. Discount CodesThanks to advances, such as in AI technology the industry is safer and more productive. Generally speaking, an automated production line is a important savings this undoubtedly assists with the development as well modernization of stainless steel pot production.