Please contact us to serve you!" >

Please contact us to serve you!" >

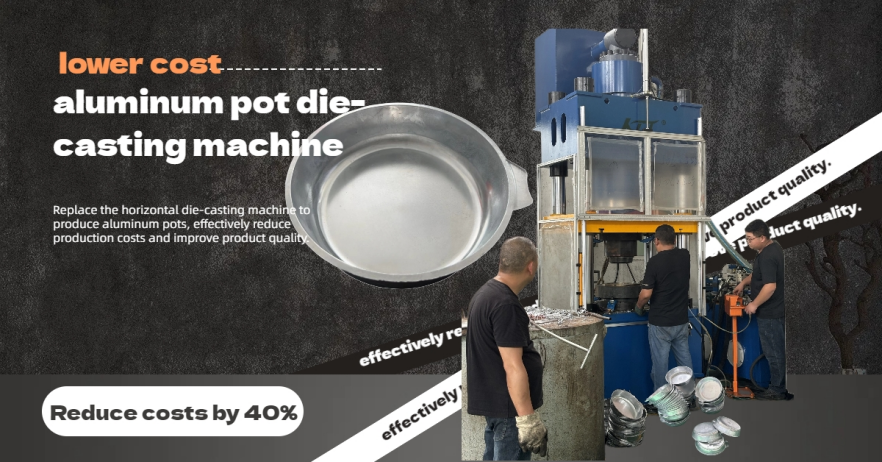

Patented new product: lower cost aluminum pot die-casting machine

(Replace the horizontal die-casting machine to produce aluminum pots, effectively reduce production costs and improve product quality.)

We provide products and service content: our company provides overall solutions, you give me product requirements, we provide a complete production line to you.

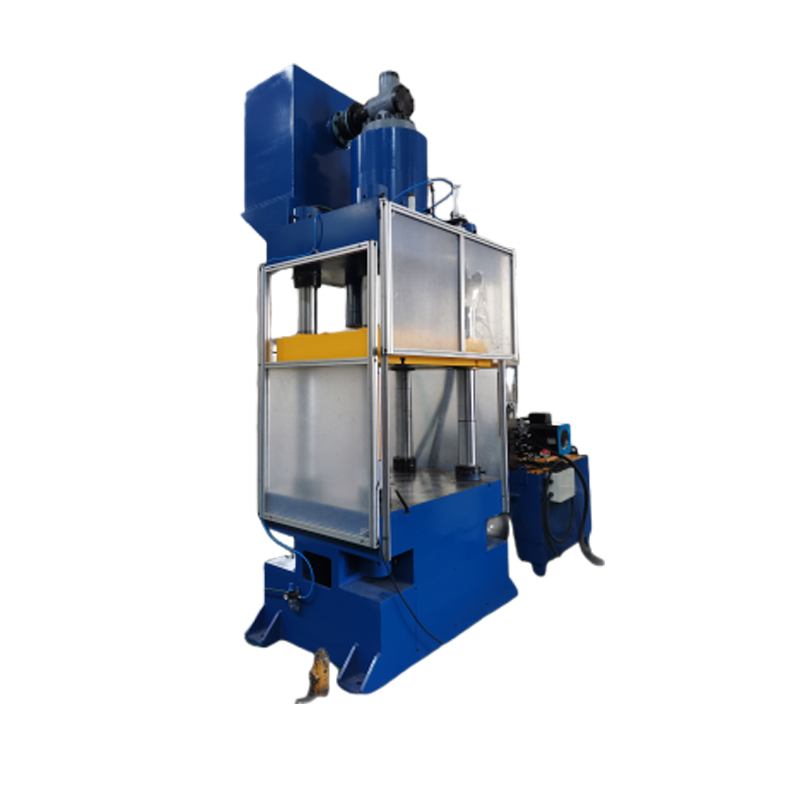

HPFS series vertical CNC die casting machine:

Equipment introduction: This series of vertical CNC die-casting machines is a new type of aluminum die-casting molding equipment newly developed by our company.

Suitable products: aluminum soup pots, pans, frying pans, cooking pots, picnic pans, non-stick pans and other die-casting products, non-stick pans can be sprayed with non-stick paint 400 degrees.

Process flow: aluminum water heating - aluminum water pouring into the mold - vertical die-casting machine compression molding - picking up - product surface treatment (manual or fully automatic operation is optional)

Aluminum-water heating furnace

Vertical die casting machine

Surface treatment equipment

Features:

1) The cost of equipment is reduced: the purchase cost of the vertical die-casting machine is only 40% of that of the horizontal die-casting machine, and the production efficiency can be doubled at the original price!

2) Reduction of process steps: There is no pouring port for the finished aluminum pot, and there is no need to cut off the process. A small amount of flash can be processed manually without trimming machine.

3) The equipment occupies a smaller area: the 400T vertical servo die-casting machine covers an area of 6㎡, and the 800T horizontal servo die-casting machine covers an area of 15㎡

4) Higher yield: the yield of vertical die-casting machines is about 98%, and the yield of horizontal die-casting machines is about 90%

5) Higher output: the output of the vertical servo die-casting machine (including the pressure holding time of 10-15s) is about 900-1000 pieces in 8 hours (including the artificial pouring of aluminum water), which is 2-3 times the output of the ordinary horizontal die-casting machine.

6) Lower equipment operating cost: (power saving) 30%, the use of servo motor to drive the oil pump is more energy efficient and lower noise than ordinary motors.

7) Automatic control: The equipment adopts numerical control to set pressure, speed and position, and can edit and save 100 programs of different products at the same time, forming automatic control and reducing manual mold testing.

8) Suitable materials: finished aluminum ingots, recycled cans (refining process)

|

category |

Vertical aluminum pot die casting machine |

Horizontal aluminum pot die casting machine |

|

quality |

Finished product rate 99% |

Finished product rate 90% |

|

Material utilization |

High material utilization, no gate and small flash area |

Low material utilization, large gate and flash area |

|

Productivity |

No need to remove gates and flash, burrs can be polished directly |

The gate and flash need to be removed first, and then the burrs are polished |

|

Equipment operation and maintenance |

Hydraulic press is easy to operate and maintain |

Die casting machines are difficult to operate and complex to maintain |

|

Equipment cost |

The total investment cost of vertical die-casting equipment is 30% lower than that of horizontal die-casting machine |

|

|

Description/ Type |

Motor Power |

Working Pressure |

Return Force |

Opening Height |

Cylinder Stroke |

Equipment Weight |

|

KW |

MPA |

KN |

mm |

mm |

KG |

|

|

HPFS-200T |

18.5 |

24 |

126 |

1000 |

700 |

8500kg |

|

HPFS-300T |

36 |

25 |

306 |

1200 |

800 |

17500kg |

|

HPFS-400T |

28.3 |

25 |

306 |

1300 |

800 |

19000kg |

|

HPFS-500T |

29 |

25 |

306 |

1200 |

900 |

25000kg |

|

HPFS-600T |

40 |

25 |

720 |

1300 |

900 |

40000kg |